COB LED Module

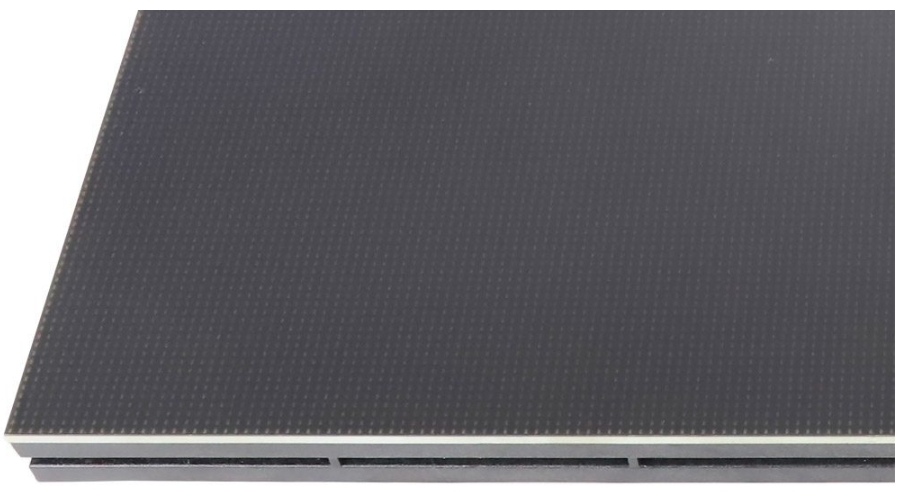

COB LED display module employs a more advanced packaging technology, which directly “attaches” the LED chips onto the PCB board. Unlike traditional LED displays that feature individual protruding LED beads, it offers a more flat and lightweight light-emitting surface. This technology not only simplifies the production process of the module but also enhances the high pixel density, heat dissipation, and protective properties of the LED display module.

COB LED display module employs a more advanced packaging technology, which directly “attaches” the LED chips onto the PCB board. Unlike traditional LED displays that feature individual protruding LED beads, it offers a more flat and lightweight light-emitting surface. This technology not only simplifies the production process of the module but also enhances the high pixel density, heat dissipation, and protective properties of the LED display module.

COB LED Display Module

COB LED display module employs a more advanced packaging technology, which directly “attaches” the LED chips onto the PCB board. Unlike traditional LED displays that feature individual protruding LED beads, it offers a more flat and lightweight light-emitting surface. This technology not only simplifies the production process of the module but also enhances the high pixel density, heat dissipation, and protective properties of the LED display module.

Advantages of COB LED display Module

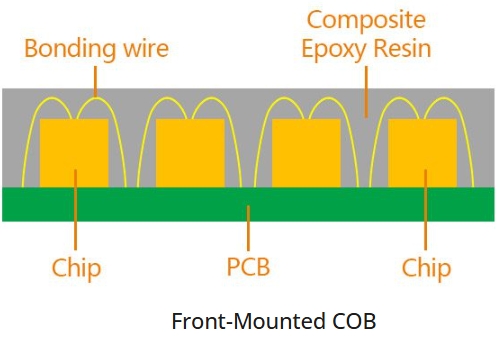

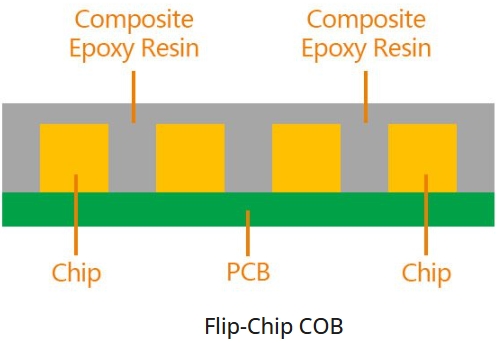

COB packaging technology is a method that directly mounts LED chips onto a printed circuit board (PCB). Both flip-chip COB (Flip-Chip COB) and front-mounted COB (Front-Mounted COB) enable a tight bond between the chip and the PCB, enhancing the performance and reliability of the device while enabling the design of smaller, thinner electronic devices.

Higher density leads to clearer visual quality

COB LED display module directly solders LED chips to PCB boards to form a flat and uniform LED surface, which helps improve the brightness and uniformity of the screen. There is no physical barrier between the light-emitting chips, and more pixels can be displayed per unit area, making the picture more delicate, the colors more full, and the visual effect more realistic.

SMD LED MODULE-POINT LIGHT GOB LED MODULE-SURFACE LIGHT

Excellent protection performance

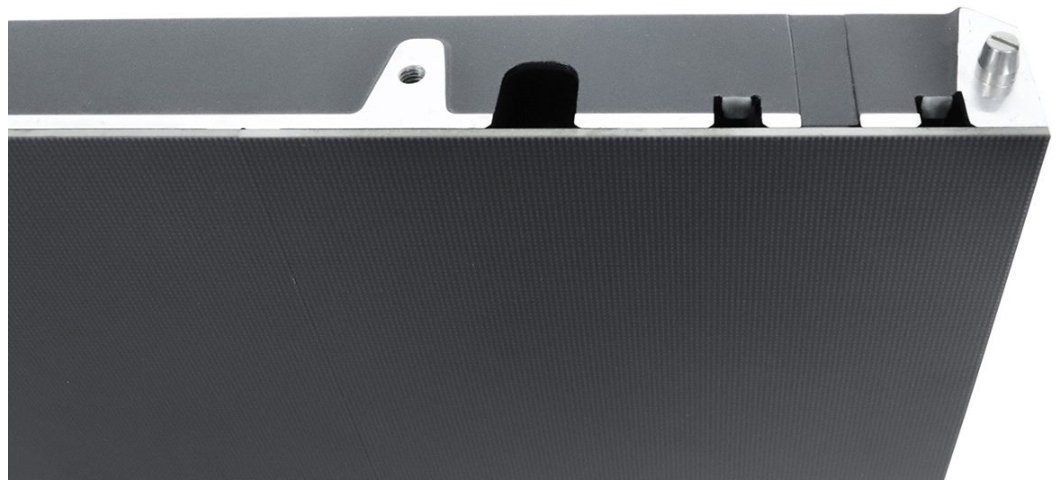

COB LED display screen adopts an overall packaging method, and the surface is directly cured and covered with polymer materials, which effectively prevents dust from entering the interior of the display screen; the module is fully sealed, and the COB display screen has excellent waterproof performance; the LED chip is completely covered in a protective layer, and there is no protruding lamp bead structure, so during transportation, installation and daily use, even if it encounters collision or vibration, it is not easy to cause the chip to fall off or be damaged.

Efficient heat dissipation

The close contact between the chip and the substrate is achieved, thereby reducing thermal resistance, allowing heat to be conducted to the substrate more quickly and dissipated quickly through the substrate, effectively reducing the operating temperature of the LED chip. Compared with traditional SMD packaging technology, COB packaging technology requires less power consumption to achieve the same brightness, generates less heat, and has less heat dissipation pressure, thereby further improving the heat dissipation effect.

Model | Pixel Pitch | LED Type | Module Size(MM) | Module Resolution | Driving Mode | Refresh Rate(Hz) | Brightness(Nits) |

P1.53-i52S-COB-320x160 | P1.53mm | Flip chip COB | 320*160 | 208*104 | 1/52 | ≥3,840 | 600 |

P1.86-i43S-COB-320x160 | P1.86mm | Flip chip COB | 320*160 | 172*86 | 1/43 | ≥3,840 | 600 |

🏠3rd Floor, Building 5, Xinlianhe Industrial Park, Baoan District, Shenzhen, Guangdong

.png)

🕙Today's Hours: 9:30 AM - 6:00 PM

LUMEN LED is a Professional LED Display Manufacturer | High Brightness & Durable Indoor and Outdoor Screens, always committed to efficiently supplying high-quality LED display products with excellent pre-sales and after-sales services to customers worldwide!

📧 info@lumen-led.cn

Tel/WhatsApp: